HP Color LaserJet CM3530fs MFP

Рейтинг

Снят с производства

Снят с производства

Тип устройства

МФУ

Технология печати

лазерная

Макс. формат

A4

Число страниц в месяц

75000

Скорость печати

A4

31

Цветность печати

цветная

Общие характеристики |

|

|---|---|

Факс |

|

Копир |

|

Сканер |

|

Тип устройства |

МФУ |

Тип |

лазерный/светодиодный |

Технология печати |

лазерная |

Макс. формат |

A4 |

Телефон |

|

Печать фотографий |

|

Цветность печати |

цветная |

Размещение |

настольный |

Область применения |

средний офис |

Число страниц в месяц |

75 000 |

Принтер |

|

Количество цветов |

4 |

Прямая печать |

|

Двусторонняя печать |

|

Пигментные чернила |

|

Печать без полей |

|

Время разогрева |

23,3 |

Макс, разрешение для ч/б печати |

|

| По Y | 600 |

| По X | 600 |

Скорость ч/б печати |

|

| A4 | 31 |

Время выхода первого отпечатка |

|

| Цветн, | 12,2 |

| Ч/б | 10,9 |

Копир |

|

Шаг масштабирования |

0,01 |

Макс, количество копий за цикл |

999 |

Время выхода первой копии |

10,9 |

Значение масштаба |

|

| Максимальное | 4 |

| Минимальное | 0,25 |

Макс, разрешение (ч/б) |

|

| По X | 600 |

| По Y | 600 |

| По Y | 300 |

| По X | 300 |

Сканер |

|

Отправка изображения по e-mail |

|

Оттенки серого |

256 |

Емкость устройства автоподачи оригиналов |

50 |

Тип сканера |

планшетный/протяжный |

Макс. формат оригинала |

A4 |

Устройство автоподачи оригиналов |

одностороннее |

Тип датчика сканера |

ПЗС (CCD) |

Макс, размер сканирования |

|

| По Y | 356 |

| По X | 216 |

Разрешение сканера |

|

| По Х (улучшенное) | 600 |

| По Х | 600 |

| По Y (улучшенное) | 600 |

Расходные материалы |

|

Количество картриджей |

4 |

Ресурс цветного картриджа/тонера |

7 000 |

Ресурс ч/б картриджа/тонера |

5 000 |

Печать на: |

|

| Карточках |

|

| Этикетках |

|

| Пленках |

|

| Глянцевой бумаге |

|

| Конвертах |

|

| Матовой бумаге |

|

| Рулоне |

|

| Фотобумаге |

|

| CD/DVD |

|

Плотность бумаги |

|

| Максимальная | 263 |

| Минимальная | 72 |

Факс |

|

Макс, скорость передачи данных |

33,6 Кбит/с |

Цветной |

|

PC Fax |

|

Телефон |

|

Caller ID |

|

Спикерфон |

|

Стандарт DECT |

|

Автоответчик |

|

АОН |

|

Беспроводная трубка |

|

Проводная трубка |

|

Языки управления |

|

|

|

|

| PCL 5e |

|

| PostScript |

|

| PostScript 3 |

|

| PCL 6 |

|

| PPDS |

|

| PostScript 2 |

|

Лотки |

|

Емкость лотка ручной подачи |

100 |

Подача бумаги |

|

| Максимальная | 850 |

| Стандартная | 350 |

Вывод бумаги |

|

| Стандартный | 250 |

| Максимальный | 250 |

Финишер |

|

Степлер |

|

Сортер |

|

Брошюровщик |

|

Интерфейсы |

|

Версия USB |

2,0 |

Bluetooth |

|

RS-232 |

|

LPT |

|

FireWire (IEEE 1394) |

|

Wi-Fi |

|

Инфракрасный порт |

|

Ethernet (RJ-45) |

|

USB |

|

Количество слотов расширения |

1 |

Количество свободных слотов расширения |

1 |

Память/Процессор |

|

Частота процессора |

515 |

Емкость жесткого диска |

80 |

Макс, объем памяти |

1 024 |

Объем памяти |

512 |

Дополнительная информация |

|

Мин. системные требования |

Intel Pentium II |

Экран |

|

Поддержка ОС |

|

| Windows |

|

| Mac OS |

|

| DOS |

|

| Linux |

|

Потребляемая мощность |

|

| В режиме ожидания | 18,1 |

| При работе | 666 |

Уровень шума |

|

| При работе | 55 |

| В режиме ожидания | 34 |

Габариты |

|

Высота |

561 |

Вес |

44,07 |

Глубина |

519 |

Ширина |

543 |

Модули

Internal components (5 of 5)

500-sheet paper feeder

Internal components (4 of 5)

250-sheet cassette

REGISTRATION ASSEMBLY

PANEL

External covers, panels, and doors

PAPER FEED

MECH-032

ADF 1

Internal components (1 of 5)

250-sheet cassette paper pickup assembly

Paper-delivery assembly

FRAME L

Right door assembly

DUPLEX

Paper feeder main body

Internal components (3 of 5)

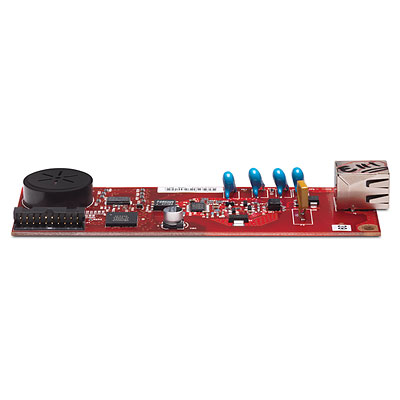

PCAs

Formatter components

COVERS and LABELS

Internal components (2 of 5)

ADF/scanner assembly

Fuser

Детали DUPLEX

| Деталь: | Duplexing unit cable assembly |

| Парткод: | RM1-5730-000CN |

| Деталь: | Pickup motor cable assembly |

| Парткод: | RM1-5731-000CN |

| Деталь: | LIFTER DRIVE ASSEMBLY |

| Парткод: | RM1-4976-000CN |

| Деталь: | Drum motor assembly |

| Парткод: | RM1-4988-000CN |

| Деталь: | PHOTO INTERRUPTER, TLP1243 |

| Парткод: | WG8-5696-000CN |

| Цена: | 350 ₽ |

| Деталь: | Cassette paper pick up drive assembly with motor |

| Парткод: | RM1-4975-000CN |

| Деталь: | Rear pre-exposure PCA |

| Парткод: | RM1-5705-000CN |

| Деталь: | Fusing drive assembly with motor |

| Парткод: | RM1-4974-000CN |

| Деталь: | DUPLEXING DRIVE ASSEMBLY |

| Парткод: | RM1-4973-000CN |

| Деталь: | Stepping motor, DC (developing disengagement) |

| Парткод: | RK2-2415-000CN |

| Цена: | 3 500 ₽ |

| Деталь: | 500-sheet feeder replacement |

| Парткод: | CE222-67901 |

| Деталь: | 500-sheet paper feeder right door kit |

| Парткод: | CC468-67906 |

| Деталь: | 500-sheet cassette |

| Парткод: | RM1-6198-000CN |

| Деталь: | Fusing connecting cable assembly |

| Парткод: | RM1-5714-000CN |

| Деталь: | Door stopper right link |

| Парткод: | RC2-4916-000CN |

| Деталь: | FAN |

| Парткод: | RK2-2416-000CN |

| Цена: | 1 000 ₽ |

| Деталь: | Switch arm |

| Парткод: | RC2-5943-000CN |

| Деталь: | Scanner flat cable (FFC) |

| Парткод: | RK2-2506-000CN |

| Деталь: | Rear cable assembly |

| Парткод: | RM1-5721-000CN |

| Деталь: | Scanner flat cable (FFC) |

| Парткод: | RK2-2508-000CN |

| Деталь: | Right door rear hinge |

| Парткод: | RC2-4895-000CN |

| Деталь: | Multipurpose tray sensor cable assembly |

| Парткод: | RM1-5737-000CN |

| Деталь: | Cable, AC (stapler power) |

| Парткод: | RK2-2501-000CN |

| Деталь: | Stapler mechanism |

| Парткод: | CC483-60107 |

| Деталь: | Stapler power supply |

| Парткод: | Q7429-60501 |

| Деталь: | 250-sheet cassette |

| Парткод: | RM1-4962-000CN |

| Деталь: | SEPARATION ROLLER ASSY |

| Парткод: | RM1-4966-000CN |

| Деталь: | REGISTRATION ASSEMBLY |

| Парткод: | RM1-4969-000CN |

| Деталь: | Блок лазера |

| Парткод: | CC468-67917 |

| Цена: | 10 300 ₽ |

| Деталь: | Аналоговый факс-модуль 500 |

| Парткод: | CC487A |

| Цена: | 49 700 ₽ |

| Деталь: | Панель управления, в сборе |

| Парткод: | CC519-67908 |

| Цена: | 11 300 ₽ |

| Деталь: | Модуль памяти |

| Парткод: | CC519-67910 |

| Цена: | 5 700 ₽ |

| Деталь: | Модуль памяти |

| Парткод: | CC519-67911 |

| Цена: | 3 100 ₽ |

| Деталь: | Модуль памяти |

| Парткод: | CC519-67912 |

| Цена: | 8 100 ₽ |

| Деталь: | Плата форматтера |

| Парткод: | CC519-67921 |

| Цена: | 23 400 ₽ |

| Деталь: | Жёсткий диск |

| Парткод: | CC519-67925 |

| Цена: | 39 900 ₽ |

| Деталь: | Датчик температуры, в сборе |

| Парткод: | RK2-3267-000CN |

| Цена: | 2 200 ₽ |

| Деталь: | Плата контроллера напряжения |

| Парткод: | RM1-5678-040CN |

| Цена: | 22 800 ₽ |

| Деталь: | COVER, RIGHT FRONT |

| Парткод: | RC2-5056-000CN |

| Деталь: | COVER, REAR |

| Парткод: | RC2-5048-000CN |

| Деталь: | COVER, LEFT |

| Парткод: | RC2-5052-000CN |

| Деталь: | COVER, REAR RIGHT |

| Парткод: | RC2-5057-000CN |

| Деталь: | COVER, RIGHT LOWER |

| Парткод: | RC2-5059-000CN |

| Деталь: | PLATE, BLANKING |

| Парткод: | RC2-5938-000CN |

| Деталь: | TRAY, PAPER DELIVERY |

| Парткод: | RL1-1941-000CN |

| Деталь: | Rib, Control panel |

| Парткод: | RC2-5179-000CN |

| Деталь: | COVER, CONTROL PANEL |

| Парткод: | RC2-5180-000CN |

| Деталь: | Cover, control panel, rear |

| Парткод: | RC2-5181-000CN |

| Деталь: | COVER, UPPER RIGHT |

| Парткод: | RC2-5182-000CN |

| Деталь: | COVER, REAR, UPPER |

| Парткод: | RC2-5185-000CN |

| Деталь: | COVER, LEFT REAR |

| Парткод: | RC2-5188-000CN |

| Деталь: | COVER, UPPER REAR |

| Парткод: | RL1-1953-000CN |

| Деталь: | Cover, right (without stapler) |

| Парткод: | RC2-5189-000CN |

| Деталь: | Holder, AC |

| Парткод: | RC2-5194-000CN |

| Деталь: | Cover, right (with stapler) |

| Парткод: | RC2-5192-000CN |

| Деталь: | Stapler, right cover assembly |

| Парткод: | RM1-5033-000CN |

| Деталь: | Узел вторичного переноса заряда |

| Парткод: | CC468-67925 |

| Цена: | 4 500 ₽ |

| Деталь: | Узел переноса изображения |

| Парткод: | CC468-67927 |

| Цена: | 24 600 ₽ |

| Деталь: | Дополнительный лоток для бумаги на 500 листов |

| Парткод: | CF084A |

| Цена: | 34 800 ₽ |

| Деталь: | GEAR Z33S CONT D |

| Парткод: | RM1-4962-070CN |

| Цена: | 5 500 ₽ |

| Деталь: | Ролик отделения бумаги из кассеты на 250 листов, в сборе |

| Парткод: | RM1-4966-020CN |

| Цена: | 1 500 ₽ |

| Деталь: | Узел захвата бумаги из кассеты на 250 листов, в сборе |

| Парткод: | RM1-4967-040CN |

| Цена: | 1 400 ₽ |

| Деталь: | Ролик захвата бумаги из кассеты на 250 листов |

| Парткод: | RM1-4968-040CN |

| Цена: | 1 000 ₽ |

| Деталь: | Кассета на 500 листов, в сборе |

| Парткод: | RM1-6198-010CN |

| Цена: | 4 200 ₽ |

| Деталь: | Узел захвата бумаги из автоподатчика документов, в сборе |

| Парткод: | CC334-60068 |

| Цена: | 2 000 ₽ |

| Деталь: | Узел автоматической подачи документов, в сборе |

| Парткод: | CC483-67907 |

| Цена: | 26 200 ₽ |

| Деталь: | Площадка отделения бумаги из автоподатчика документов, в сборе |

| Парткод: | Q2665-60125 |

| Цена: | 800 ₽ |

| Деталь: | Lifter cable assembly |

| Парткод: | RM1-5742-000CN |

| Деталь: | Cover, front inner lower |

| Парткод: | RL1-1914-000CN |

| Деталь: | Cover, front inner upper |

| Парткод: | RC2-5006-000CN |

| Деталь: | Cover, front inner lower |

| Парткод: | RL1-1915-000CN |

| Деталь: | COVER, LEFT LOWER |

| Парткод: | RC2-5069-000CN |

| Деталь: | WASTE TONER DETECT ASSEMBLY |

| Парткод: | RM1-5696-000CN |

| Цена: | 900 ₽ |

| Деталь: | Waste toner duct assembly (motor) |

| Парткод: | RM1-4977-000CN |

| Деталь: | SPRING, TENSION |

| Парткод: | RU6-2236-000CN |

| Деталь: | Spring, ground |

| Парткод: | RU6-2237-000CN |

| Цена: | 360 ₽ |

| Деталь: | Lever, cartridge pressure front |

| Парткод: | RC2-3983-000CN |

| Деталь: | SEAL, WASTE TONER BOX |

| Парткод: | RC2-4780-000CN |

| Цена: | 500 ₽ |

| Деталь: | LOCK, DOOR |

| Парткод: | RC2-5937-000CN |

| Цена: | 600 ₽ |

| Деталь: | LEVER, BOX PRESENCE DETECT |

| Парткод: | RC2-5951-000CN |

| Цена: | 320 ₽ |

| Деталь: | SPRING, COMPRESSION |

| Парткод: | RU6-2568-000CN |

| Цена: | 800 ₽ |

| Деталь: | 250-sheet cassette paper pickup assembly |

| Парткод: | RM1-4967-000CN |

| Деталь: | 250-sheet cassette paper pickup roller |

| Парткод: | RM1-4968-000CN |

| Деталь: | Paper-delivery assembly |

| Парткод: | RM1-4970-000CN |

| Деталь: | Печь, в сборе |

| Парткод: | CE506A |

| Цена: | 13 500 ₽ |

| Деталь: | (CET6772) Прижимной вал |

| Парткод: | LPR-CP3525 |

| Цена: | 2 000 ₽ |

| Деталь: | (CET1559) Термоплёнка *смазка в комплекте |

| Парткод: | RM1-3131-FILM |

| Деталь: | Термоплёнка |

| Парткод: | RM1-3146-FILM |

| Цена: | 2 100 ₽ |

| Деталь: | Нагревательный элемент узла термозакрепления |

| Парткод: | RM1-3146-HEAT |

| Деталь: | RIGHT DOOR ASSEMBLY |

| Парткод: | RM1-4957-000CN |

| Деталь: | Tray 1 pickup roller |

| Парткод: | RL1-1928-000CN |

| Деталь: | Duplex reverse guide kit |

| Парткод: | CC468-67913 |

| Цена: | 1 500 ₽ |

| Деталь: | Главный редуктор, в сборе |

| Парткод: | CC468-67918 |

| Цена: | 35 700 ₽ |

| Деталь: | Контейнер для отработанного тонера |

| Парткод: | CE254A |

| Цена: | 1 600 ₽ |

| Деталь: | Передний рычаг прижима картриджа |

| Парткод: | RC2-3983-030CN |

| Цена: | 500 ₽ |

| Деталь: | Узел выхода бумаги, в сборе |

| Парткод: | RM1-4970-060CN |

| Цена: | 2 100 ₽ |

| Деталь: | Drawer connector (Tray 3) |

| Парткод: | VS1-7257-007CN |

| Деталь: | Drawer connector holder (Tray 3) |

| Парткод: | RC2-5416-000CN |

| Деталь: | Link, door stopper right |

| Парткод: | RC2-4916-000CN |

| Деталь: | Cover, right lower inner |

| Парткод: | RC2-5019-000CN |

| Деталь: | Interlock link |

| Парткод: | RC2-5120-000CN |

| Деталь: | Interlock switch mount |

| Парткод: | RC2-5123-000CN |

| Деталь: | Interlock link switch arm |

| Парткод: | RC2-5121-000CN |

| Деталь: | Interlock link |

| Парткод: | RC2-5119-000CN |

| Деталь: | Interlock link |

| Парткод: | RC2-5118-000CN |

| Деталь: | Switch lever |

| Парткод: | RC2-5124-000CN |

| Деталь: | SHAFT |

| Парткод: | RC2-5913-000CN |

| Деталь: | SPRING, TORSION |

| Парткод: | RC2-5934-000CN |

| Деталь: | Cartridge lock lever |

| Парткод: | RC2-5954-000CN |

| Деталь: | SPRING, TORSION |

| Парткод: | RC2-5958-000CN |

| Деталь: | Interlock link |

| Парткод: | RC2-5122-000CN |

| Деталь: | Power supply button |

| Парткод: | RL1-1947-000CN |

| Деталь: | PHOTO INTERRUPTER, TLP1243 |

| Парткод: | WG8-5696-000CN |

| Цена: | 350 ₽ |

| Деталь: | Front cable assembly |

| Парткод: | RM1-6998-000CN |

| Деталь: | Density detect sensor assembly |

| Парткод: | RM1-4953-000CN |

| Деталь: | Lower pick up guide assembly |

| Парткод: | RM1-4980-000CN |

| Деталь: | ITB assembly service kit |

| Парткод: | CC468-67907 |

| Деталь: | Switch cable assembly |

| Парткод: | RM1-5718-000CN |

| Деталь: | Front lock arm assembly |

| Парткод: | RM1-5532-000CN |

| Деталь: | Power supply switch assembly |

| Парткод: | RM1-5697-000CN |

| Деталь: | DOOR SWITCH ASSEMBLY |

| Парткод: | RM1-5732-000CN |

| Деталь: | SWITCH |

| Парткод: | WC4-5171-000CN |

| Деталь: | Transfer roller assembly service kit |

| Парткод: | CC468-67914 |

| Цена: | 3 200 ₽ |

| Деталь: | Rear lock arm assembly |

| Парткод: | RM1-5533-000CN |

| Деталь: | High-voltage power supply lower PCA (HVPS-D) |

| Парткод: | RM1-5680-000CN |

| Деталь: | High-voltage power supply upper PCA (HVPS-T) |

| Парткод: | RM1-5681-000CN |

| Деталь: | DC controller PCA |

| Парткод: | RM1-5678-000CN |

| Деталь: | Low-voltage power supply PCA(110 v) |

| Парткод: | RM1-5689-000CN |

| Деталь: | Low-voltage power supply PCA(220 v) |

| Парткод: | RM1-5690-000CN |

| Цена: | 48 900 ₽ |

| Деталь: | Interconnect board (ICB) |

| Парткод: | CC453-60001 |

| Деталь: | Formatter PCA |

| Парткод: | CC452-60001 |

| Деталь: | Scanner controller board (SCB) |

| Парткод: | CC454-60002 |

| Деталь: | Hard drive, 80GB 2.5-inch SATA ROHS |

| Парткод: | CC519-67904 |

| Деталь: | SATA hard drive cable power/data |

| Парткод: | CC519-67905 |

| Цена: | 2 300 ₽ |

| Деталь: | Fax controller PCA |

| Парткод: | CC456-60001 |

| Деталь: | Fax cable |

| Парткод: | CC519-67907 |

| Цена: | 850 ₽ |

| Деталь: | Накладка на панель управления |

| Парткод: | CC519-40015 |

| Цена: | 550 ₽ |

| Деталь: | Правая крышка, в сборе |

| Парткод: | RM1-8123-040CN |

| Цена: | 12 300 ₽ |

| Деталь: | Fan cable assembly |

| Парткод: | RM1-5746-000CN |

| Цена: | 700 ₽ |

| Деталь: | SPRING, TENSION |

| Парткод: | RU6-2436-000CN |

| Деталь: | SPRING, LEAF |

| Парткод: | RC2-5970-000CN |

| Деталь: | TAB |

| Парткод: | RC2-5909-000CN |

| Деталь: | SHUTTER |

| Парткод: | RC2-5910-000CN |

| Деталь: | COVER |

| Парткод: | RC2-5912-000CN |

| Деталь: | SPRING, TORSION |

| Парткод: | RC2-5958-000CN |

| Деталь: | HOLDER, CARTRIDGE LOCK LEVER |

| Парткод: | RC2-5955-000CN |

| Деталь: | LEVER, CARTRIDGE LOCK |

| Парткод: | RC2-5954-000CN |

| Деталь: | COVER |

| Парткод: | RC2-5962-000CN |

| Деталь: | SPRING, COMPRESSION |

| Парткод: | RU6-2318-000CN |

| Деталь: | SPRING, COMPRESSION |

| Парткод: | RU6-2316-000CN |

| Деталь: | TAB |

| Парткод: | RC2-4428-000CN |

| Деталь: | LEVER, SHUTTER |

| Парткод: | RU6-4415-000CN |

| Деталь: | SHUTTER |

| Парткод: | RC2-4413-000CN |

| Деталь: | Shutter rear arm |

| Парткод: | RC2-4407-000CN |

| Деталь: | Shutter front arm |

| Парткод: | RC2-4406-000CN |

| Деталь: | Sensor unit, Tmp/Hum sensor |

| Парткод: | RK2-2229-000CN |

| Деталь: | BASE |

| Парткод: | RL1-2144-000CN |

| Деталь: | Toner sensor holder assembly |

| Парткод: | RM1-5700-000CN |

| Деталь: | BASE |

| Парткод: | RL1-1923-000CN |

| Деталь: | BASE ASSEMBLY |

| Парткод: | RM1-4979-000CN |

| Деталь: | Lower cartridge guide assembly |

| Парткод: | RM1-4984-000CN |

| Деталь: | CONNECTING CABLE ASSEMBLY |

| Парткод: | RM1-5749-000CN |

| Деталь: | Sensor cable assembly |

| Парткод: | RM1-5740-000CN |

| Деталь: | Sensor cable assembly |

| Парткод: | RM1-5741-000CN |

| Деталь: | Motor/sensor cable assembly |

| Парткод: | RM1-5752-000CN |

| Деталь: | FAN |

| Парткод: | RK2-2418-000CN |

| Цена: | 2 700 ₽ |

| Деталь: | CONTROL PANEL ASSEMBLY |

| Парткод: | CC519-60115 |

| Деталь: | ADF feed roller kit |

| Парткод: | CC519-67909 |

| Деталь: | ADF ASSEMBLY |

| Парткод: | CC483-60103 |

| Деталь: | Scanner assembly (ADF assembly and SCB PCA are not included) |

| Парткод: | CC519-67914 |

| Деталь: | Control-panel cable |

| Парткод: | CC519-60107 |

| Деталь: | Scanner controller board (SCB) |

| Парткод: | CC454-60002 |

| Деталь: | PCI express RoHS cable |

| Парткод: | 5851-3141 |

| Деталь: | CC519-67901 |

| Парткод: | Fuser/Fixing service kit110 v |

| Деталь: | CC519-67902 |

| Парткод: | Fuser/Fixing service kit 220 v |

Коды ошибок

10.00.YY

11.XX

13.01

13.04

13.05

13.06

13.12

13.13

13.1C

13.20

13.21

13.2E

13.30.00

20

22

30.01.02

30.01.03

30.01.08

30.01.14

30.01.18

30.01.19

30.01.23

30.01.25

30.01.36

30.01.39

30.01.4

30.01.40

30.01.42

30.01.43

30.01.44

30.01.45

30.01.46

40

41.3

41.5

41.X

49.XXXXX

50.1

50.2

50.3

50.4

50.5

50.7

50.8

50.9

51.1Y

51.2Y

52.00

52.20

53.10.0X

54.01

55.00.YY

55.01.YY

55.02.YY

55.03.YY

55.04.YY

55.05

56.01

56.02

57.03

57.04

57.07

59.30

59.40

59.5Y

59.6Y

59.B0

59.BO

59.C0

59.F0

59.XY

60.02

60.03

68.X

69.X

79.XXXX

8X.YYYY

Описание

| Error code: | 10.00.YY |

| Display: | 10.XX.YY SUPPLY MEMORY ERROR |

| Description: | The MFP cannot read or write to at least one print cartridge e-label or an e-label is missing from a print cartridge. E-label is damaged. |

| Remedy: | 1. Reinstall the print cartridge, or install a new HP print cartridge. 2. Verify that connector J97 on the DC controller PCA is firmly seated. |

| Error code: | 11.XX |

| Display: | 11.XX INTERNAL CLOCK ERROR |

| Description: | The real time clock has experienced an error. |

| Remedy: | 1. Power cycle the product to see if the message clears. 2. If possible, print a configuration page to record product information, and then perform an NVRAM initialization routine. If the initialization routine is successful, you will need to re-enter several configuration parameters (such as the page count and the serial number). 3. If the error persists, replace the formatter PCA. |

| Error code: | 13.01 |

| Display: | 13.01 Paper feed 1, Paper late jam |

| Description: | • The leading edge of the paper fed from Tray 1 stopped before reaching the registration sensor (C). • The leading edge of the paper fed from Tray 2 stopped before reaching the registration sensor (B). • The leading edge of the paper fed from Tray 3 stopped before reaching the registration sensor (A-1). • The leading edge of the paper fed from Tray 4 stopped before reaching the registration sensor (A-2). • The leading edge of the paper fed from Tray 5 stopped before reaching the registration sensor (A-3).89A |

| Remedy: | Follow the onscreen instructions to locate and remove the paper or obstruction. |

| Error code: | 13.04 |

| Display: | 13.04 Jams inside right door |

| Description: | The paper stopped at the registration sensor (A). |

| Remedy: | Follow the onscreen instructions to locate and remove the paper or obstruction. |

| Error code: | 13.05 |

| Display: | 13.05 Paper Late Jam Between Sensors D and F |

| Description: | The leading edge of the paper stopped between the registration sensor (D) and the fuser-output sensor (F). |

| Remedy: | Follow the onscreen instructions to locate and remove the paper or obstruction. |

| Error code: | 13.06 |

| Display: | 13.06 Paper Jam In Fuser |

| Description: | The paper stopped at the fuser-output sensor (F). |

| Remedy: | Follow the onscreen instructions to locate and remove the paper or obstruction. |

| Error code: | 13.12 |

| Display: | 13.12 Paper Late Jam In Duplex Area Sensors H - D |

| Description: | The duplex refeed paper stopped between the duplexer-delivery sensor (H) and the registration sensor (D). |

| Remedy: | Follow the onscreen instructions to locate and remove the paper or obstruction. |

| Error code: | 13.13 |

| Display: | 13.13 Paper Stop Jam In Duplex Area Sensors G - H |

| Description: | The duplex refeed paper stopped between the switchback sensor (G) and the duplexerdelivery sensor (H). |

| Remedy: | Follow the onscreen instructions to locate and remove the paper or obstruction. |

| Error code: | 13.1C |

| Display: | 13.1C Fuser Wrap Jam, Paper in Fuser |

| Description: | The paper is wrapping at the fuser. |

| Remedy: | Follow the onscreen instructions to locate and remove the paper or obstruction. |

| Error code: | 13.20 |

| Display: | 13.20 - Jam inside rear bin Clear jam then open and close front door |

| Description: | Media is jammed in the output bin. |

| Remedy: | Open the rear output bin and gently remove the jammed media. Follow the instructions in the onscreen dialog box. |

| Error code: | 13.21 |

| Display: | 13.21 Door Open Jam |

| Description: | The paper position is unknown. |

| Remedy: | Follow the onscreen instructions to locate and remove the paper or obstruction. |

| Error code: | 13.2E |

| Display: | 13.2E Paper Late Jam Near Fuser at Sensors F - J |

| Description: | The paper stopped between the fuser-output sensor (F) and the output-bin-full sensor (J). |

| Remedy: | Follow the onscreen instructions to locate and remove the paper or obstruction. |

| Error code: | 13.30.00 |

| Display: | 13.30.00 Jam inside right door |

| Description: | A jam is in the pickup area of Tray 1. |

| Remedy: | Clear the jam. - Close the door to allow the product to attempt to clear the jam. - Run a service test. - Replace the paper input unit. - Replace the Tray 1 pickup rollers. - Replace Tray 1. |

| Error code: | 20 |

| Description: | Vertical image or label drift |

| Causes: | The printer is using non-continuous labels but is configured in continuous mode. The media sensor is positioned incorrectly. The media sensor is calibrated improperly. The platen roller is dirty. Improper printhead pressure settings (toggles). Improperly loaded ribbon or media. Incompatible media. |

| Remedy: | Configure the printer for non-continuous and run calibration routine, if necessary. Ensure that the media sensor is properly positioned to read a single/consistent interlabel gap. See Calibrate Media and Ribbon Sensor Sensitivity on page 90. Clean the platen roller. See Clean the Printhead and Platen Roller on page 131. Adjust the printhead pressure to ensure proper functionality. Verify that the printer is loaded properly. Ensure that the interlabel gaps or notches are 2 to 4 mm and consistently placed. Media must not exceed minimum specifications for mode of operation. |

| Error code: | 22 |

| Description: | Loss of printing registration on labels. Excessive vertical drift in top-of-form registration. |

| Causes: | The platen roller is dirty. Media guides are positioned improperly. The media type is set incorrectly. The media is loaded incorrectly. |

| Remedy: | Clean the platen roller according to the instructions in Clean the Printhead and Platen Roller on page 131. Ensure that the media guides are properly positioned. Set the printer for the correct media type (gap/notch, continuous, or mark). See Set Media Type on page 81. Load media correctly. See Load Media on page 58. |

| Error code: | 30.01.02 |

| Display: | 30.01.02 ADF paper jam |

| Description: | Scanner calibration failure The scanner calibration failed. |

| Remedy: | 1. Turn the product off, and then on again. 2. After the product warms up, repeat the calibration process. Device Maintenance / Calibrate-Cleaning / Calibrate Scanner 3. If the error persists, clean the scanner glass and calibration strips. NOTE: Dust might appear on the underside of the glass, but this cannot be cleaned. a. Press the power button to turn the product off, and then disconnect the power cable from the electrical outlet. b. Open the scanner lid. c. Use a soft, lint-free cloth moistened with water to clean the calibration white strips and reflector plate (see call-outs). Also clean the document feeder glass, flatbed glass and plastic lid backing. NOTE: If needed, lens cleaner or nonabrasive glass cleaner can be applied to the cloth before cleaning the glass. Spray only onto the cloth and not directly onto the glass or device. Do not spray water or glass cleaner on the glass as it can seep under it and possibly damage the printer. Do not use abrasives, acetone, benzene, ethyl alcohol, or carbon tetrachloride on the glass; these can damage it and/or leave residue on the glass resulting in degraded copy/scan quality. 4. If the error persists, replace the Integrated Scanning Assembly (ISA). |

| Error code: | 30.01.03 |

| Display: | 30.01.03 Pick error |

| Description: | The document feeder sensors failed to detect a successful pick. |

| Remedy: | - Open the ADF feeder and remove the jammed media. Close the ADF feeder. - Reload the document and press Start. - If the error persists, run a sensors diagnostic test to verify that the skew front and skew back sensors are functioning correctly. - Verify that the pickup roller, the feed roller assembly, the separation belt assembly, and the registration roller assembly are clean and undamaged. |

| Error code: | 30.01.08 |

| Display: | 30.01.08 Home position error |

| Description: | Home position error The scanner optic failed to return to the home position. |

| Remedy: | 1. Turn the product off, and then on again. 2. Observe the movement of the optics assembly. 3. If the error persists, run the scanner motor test under component test. Administration/ Troubleshooting/Scanner tests/Flatbed motor test 4. If issue still remains and firmware has been upgraded replace scanner control board (SCB). IMPORTANT: Check all cables on SCB for proper connection and seating before replacing any parts and test. 5. If the error persists, replace the integrated scanning assembly (ISA). |

| Error code: | 30.01.14 |

| Display: | 30.01.14 Scan system EEPROM error |

| Description: | Scan system EEPROM error Scanner control board (SCB) EEPROM error. |

| Remedy: | 1. Turn the product off, and then on again.2. Ensure all connectors on the SCB are connected and properly seated.3. Ensure the MFP has at latest SCB firmware version.4. Replace the SCB. |

| Error code: | 30.01.18 |

| Display: | 30.01.18 Scanner Error |

| Description: | Scanner Error Scanner internal optical sensor error. |

| Remedy: | 1. Turn the product off, and then on again.2. Make sure that all the connectors on the SCB are properly seated.3. Make sure that the MFP has the latest SCB firmware version.4. Replace the SCB.5. If the error persists, replace the integrated scanning assembly (ISA) |

| Error code: | 30.01.19 |

| Display: | 30.01.19 Scanner lamp error |

| Description: | Scanner lamp error Scanner internal lamp sensor error. |

| Remedy: | 1. Turn the product off, and then on again.2. Determine if the scanner lamp turns on and off approximately 12 second after the product turns on.3. Test the lower lamp using the scanner test located in the Diagnostics menu.4. Re-seat the interconnect cables between the optical carriage and the SCB.5. Replace the integrated scanning assembly (ISA) |

| Error code: | 30.01.23 |

| Display: | 30.01.23 Scanner calibration failure |

| Description: | The scanner calibration failed. |

| Remedy: | 1. Turn the product off, and then on again. 2. After the product warms up, repeat the calibration process. 3. If the error persists, replace the scanner. |

| Error code: | 30.01.25 |

| Display: | 30.01.25 Scanner failure |

| Description: | The copy-process board (CPB) failed. |

| Remedy: | 1. Turn the product off and then on. 2. Check the CPB LED. 3. Verify that the CPB connections are correct. 4. Verify the cable from the scanner to the formatter is not plugged in backwards. 5. Replace the CPB. |

| Error code: | 30.01.36 |

| Display: | 30.01.36 Upgrade Error try downloading upgrade again |

| Description: | Upgrade Error Try downloading upgrade again Scanner firmware upgrade error. |

| Remedy: | 1. Re-send the scanner firmware upgrade. 2. If the error persists, replace the SCB. |

| Error code: | 30.01.39 |

| Display: | 30.01.39 Scanner failure |

| Description: | There was an AFE1 (analog front-end) failure. |

| Remedy: | 1. Turn the product off and then on. 2. Check the flat cables on the SCB. 3. Check the LEDs on the SCB. 4. Replace the SCB. 5. Replace the scanner |

| Error code: | 30.01.4 |

| Display: | 30.01.41 Scanner failure |

| Description: | There was a SCB error. |

| Remedy: | 1. Turn the product off and then on. 2. Replace the SCB |

| Error code: | 30.01.40 |

| Display: | 30.01.40 Scanner failure |

| Description: | The scanner AFE 2 failed. |

| Remedy: | 1. Turn the product off and then on. 2. Check the flat cables on the SCB. 3. Check the LEDs on the SCB. 4. Replace the SCB. 5. Replace the scanner. |

| Error code: | 30.01.42 |

| Display: | 30.01.42 Scanner error |

| Description: | Scanner error Internal product communication error. |

| Remedy: | 1. Turn the product off, and then on again.2. If the error persists, turn the product off, and then check all scanner control board (SCB) connectors are fully seated.3. If this error occurs after a formatter, fax card or hard disk has been replaced, check that the formatter connectivity LED (smile face icon on the formatter) is illuminated. Check the fax card for proper seating on the formatter. (If fax card is not properly seated it can prevent the formatter from seating properly in the product. 4. Verify that all cables are connected to the product and to the interconnect board / formatter and SCB. 5. If the error persists, replace the scanner control board (SCB). |

| Error code: | 30.01.43 |

| Display: | 30.01.43 Scanner memory failure |

| Description: | Scanner memory failure Scan memory error. |

| Remedy: | 1. Turn the product off, and then on again. 2. If the error persists, turn the product off, and then re-seat the formatter. 3. If the error persists, replace the formatter. |

| Error code: | 30.01.44 |

| Display: | 30.01.44 |

| Description: | Copy processor (CPB) / scanner control board (SCB) communication error |

| Remedy: | 1. Turn the product off, and then on again. 2. If the error persists, turn the product off, and then check the scanner cable. 3. Upgrade the firmware. 4. If the error persists, turn the product off, and then re-seat the formatter. 5. If the error persists, replace the scanner control board (SCB) or the formatter. |

| Error code: | 30.01.45 |

| Display: | 30.01.45 |

| Description: | Internal copy processor board (CPB) communication error. CPB code assertion error for the copy processor board firmware. |

| Remedy: | 1. Turn the product off, and then on again. 2. If the error persists, turn the product off, and then re-seat the formatter. 3. Upgrade the firmware. 4. If the error persists, replace the scanner control board (SCB). 5. If the error persists, replace the formatter. |

| Error code: | 30.01.46 |

| Display: | 30.01.46 Scanner Error |

| Description: | Scanner Error The firmware cannot find the copy processor board (CPB). |

| Remedy: | 1. Turn the product off, and then on again. 2. If the error persists, turn the product off, and then re-seat the formatter. 3. If the error persists, replace the scanner control board (SCB). |

| Error code: | 40 |

| Display: | Scanner locked |

| Description: | 10-348 ERROR 40 FUSER MAIN LAMP FAILURE Note If this failure reoccurs three times successively, an Engine NVRAM value is set preventing further printer use until the Clear Tech Rep Fault, Clear <10-348 & 10-350> is run. |

| Causes: | 1. Deformed paper sensor actuator or faulty sensor. 2. SMPS PBA or Main PBA is defective 3. Faulty cables or connectors. |

| Remedy: | Switch printer power OFF. Remove the Fuser Assembly. Warning Fuser may be very hot. Use extreme caution to prevent burns. Measure the resistance between the Fuser Assembly connector P600-4 and P600-6. Does the resistance measure between 20K and 100K ohms? Y↓N→ Replace the Fuser Assembly. Reinstall Fuser. Remove the Rear Cover, Rear Shield and the Rear Shield Bracket. Measure the resistance between P404A-1 and P404A-2 on the Engine Control Board. Does the resistance measure between 20K and 100K ohms? Y↓N→ Repair or replace the wiring harness between the Engine Control Board and the Fuser. Replace the Engine Control Board. |

| Error code: | 41.3 |

| Display: | 41.3 UNEXPECTED SIZE IN TRAY <X> |

| Description: | You have configured the tray for a different size of paper than the print job requires. NOTE: This error can be caused by a multi feed problem. Open, and then close, the cartridge door to clear the error message. If the error persists, and the tray is correctly configured, try cleaning the Tray 1 pickup roller (or you might have to replace the roller). |

| Remedy: | 1. Reload the tray with the correct paper size. 2. Make sure the paper size that is specified in the software program, the printer driver, and the control panel are all the same. 3. Press the OK button and scroll to the TRAY <X> SIZE = <Size> option. Reconfigure the size in a tray to match the size required for the print job. 4. If the error does not clear, turn the product off and then on. 5. If the message persists, contact an HPauthorized service or support provider. |

| Error code: | 41.5 |

| Display: | 41.5 UNEXPECTED TYPE IN TRAY X |

| Description: | The device senses a different media type than what is configured in the tray. |

| Remedy: | 1. Press "OK" to print from a different tray. 2. To print from the current tray, load the tray with the size and type indicated. Ensure that all trays are configured correctly before printing again |

| Error code: | 41.X |

| Display: | 41.X ERROR |

| Description: | A temporary printing error occurred. |

| Remedy: | 1. Press OK to see if the page will print. If necessary, turn the product off and then on. 2. Verify that the loaded paper meets HP specifications. If pages stick together, the paper detect sensors will detect a sheet of paper longer than what is expected in the product. 3. Verify that all paper size settings on the control panel, in the print driver settings, and in the software program match. 4. Verify that the correct size paper is loaded in the input tray. |

| Error code: | 49.XXXXX |

| Display: | 49.XXXXX ERROR |

| Description: | A critical firmware error has occurred. |

| Remedy: | 1. Turn the device off and then on. 2. Try to determine whether the error occurs intermittently, while printing, or when turning on the device. 3. If the error appears while printing, determine whether it occurs when printing from a specific computer, a specific application, or a specific file. If all other computers, applications, or files can print without the error, then the problem may be only within one print job or computer. Make sure the computer has the most current printer drivers, or use a generic printer driver. 4. Check for the latest firmware image version at the bottom of the page. If this firmware image is newer than the one installed on the device and the device can receive a firmware update, download the newer firmware upgrade. 5. Try printing a job from a different software program. If the job prints, go back to the first program and try printing a different file. If the message appears only with a certain software program or print job, contact the software vendor for assistance. 6. If the message persists, contact HP Support |

| Error code: | 50.1 |

| Display: | 50.1 FUSER ERROR |

| Description: | AC power is not being provided to the fuser assembly. AC voltage is necessary to generate heat in the fuser assembly. |

| Remedy: | 1. Verify that the fuser power cable at the back of the device is connected and the ECU is fully seated. 2. If the message persists, replace the fuser assembly. |

| Error code: | 50.2 |

| Display: | 50.<X> Fuser To continue turn off then on |

| Description: | A fuser error has occurred. fuser warm up service. |

| Remedy: | - Turn the product off, and then on. - Reseat the connection to the fuser and the DC controller. - Replace the fuser. - Replace the upper cable guide assembly. - Replace the low voltage power supply. - Replace the DC controller |

| Error code: | 50.3 |

| Display: | 50.<X> Fuser To continue turn off then on |

| Description: | A fuser error has occurred. high fuser temperature |

| Remedy: | - Turn the product off, and then on. - Reseat the connection to the fuser and the DC controller. - Replace the fuser. - Replace the upper cable guide assembly. - Replace the low voltage power supply. - Replace the DC controller |

| Error code: | 50.4 |

| Display: | 50.<X> Fuser To continue turn off then on |

| Description: | A fuser error has occurred.f aulty fuser. |

| Remedy: | - Turn the product off, and then on. - Reseat the connection to the fuser and the DC controller. - Replace the fuser. - Replace the upper cable guide assembly. - Replace the low voltage power supply. - Replace the DC controller |

| Error code: | 50.5 |

| Display: | 50.<X> Fuser To continue turn off then on |

| Description: | A fuser error has occurred. inconsistent fuser. |

| Remedy: | - Turn the product off, and then on. - Reseat the connection to the fuser and the DC controller. - Replace the fuser. - Replace the upper cable guide assembly. - Replace the low voltage power supply. - Replace the DC controller |

| Error code: | 50.7 |

| Display: | 50.X FUSER ERROR To continue turn off then on |

| Description: | A fuser error has occurred. fuser pressure release malfunction |

| Remedy: | 1. Turn the device off, and allow it to cool. 2. Verify that the correct model of fuser is installed. 3. Verify that the correct voltage fuser is installed. 4. Reinstall the fuser, and check the connection between the fuser and the high-voltage power supply. Replace the high-voltage power supply if the connector is damaged. 5. Replace the fuser. Replace the dc controller PCA. See DC controller PCA on page 357. 7. Replace the high-voltage power supply. |

| Error code: | 50.8 |

| Display: | 50.X FUSER ERROR To continue turn off then on |

| Description: | A fuser error has occurred. low fuser temperature |

| Remedy: | 1. Turn the device off, and allow it to cool. 2. Verify that the correct model of fuser is installed. 3. Verify that the correct voltage fuser is installed. 4. Reinstall the fuser, and check the connection between the fuser and the high-voltage power supply. Replace the high-voltage power supply if the connector is damaged. 5. Replace the fuser. Replace the dc controller PCA. See DC controller PCA on page 357. 7. Replace the high-voltage power supply. |

| Error code: | 50.9 |

| Display: | 50.X FUSER ERROR To continue turn off then on |

| Description: | A fuser error has occurred. high fuser temperature |

| Remedy: | 1. Turn the device off, and allow it to cool. 2. Verify that the correct model of fuser is installed. 3. Verify that the correct voltage fuser is installed. 4. Reinstall the fuser, and check the connection between the fuser and the high-voltage power supply. Replace the high-voltage power supply if the connector is damaged. 5. Replace the fuser. Replace the dc controller PCA. See DC controller PCA on page 357. 7. Replace the high-voltage power supply. |

| Error code: | 51.1Y |

| Display: | 51.1Y PRINTER ERROR |

| Description: | A laser error has occurred. Y 0 - Black 1 - Cyan 2 - Magenta 3 - Yellow |

| Remedy: | 1. Turn the printer off then on. 2. Reseat the connectors (J1002 - Y, J1003 - C, J1004 - M, J1005 - K) between the laser/scanner and DC controller PCB. 3. Upgrade formatter and DC Controller firmware. 4. Replace the defective laser/scanner assembly. Calibrate the printer after replacing the laser/ scanner. |

| Error code: | 51.2Y |

| Display: | 51.2Y PRINTER ERROR |

| Description: | A laser beam error has occurred. Y 0 - Black 1 - Cyan 2 - Magenta 3 - Yellow |

| Remedy: | 1. Turn the printer off then on. 2. Upgrade formatter and DC Controller firmware, which can be found in a single. 3. Reseat the connectors (J1002 - Y, J1003 - C, J1004 - M, J1005 - K) between the laser/scanner and DC controller PCB. 4. Replace the defective laser/scanner assembly. Calibrate the printer after replacing the laser/ scanner |

| Error code: | 52.00 |

| Display: | 52.00 ERROR |

| Description: | A scanner motor error has occurred. Scanner motor rotation is verified at the initialization of a print job. |

| Remedy: | 1. Verify that the scanner motor connector and the ribbon cable from the ECU are firmly seated on the laser/scanner assembly. 2. Verify that the scanner motor connector is firmly seated in connector J402 on the ECU. You might have to remove the main cooling fan to see this connection. 3. Verify that the ribbon cable installed in connector J403 on the ECU is fully seated You must remove the ECU in order to verify this connection. 4. If the message persists, replace the laser/scanner assembly. |

| Error code: | 52.20 |

| Display: | 52.XY ERROR To continue turn off then on |

| Description: | A temporary printing error has occurred. laser/scanner motor rotation speed error |

| Remedy: | 1. Turn the device off, and then turn the device on. 2. Reseat the connectors between the laser/scanner and the dc controller PCA (J801 and J321). 3. Replace the laser/scanner assembly. 4. Replace the dc controller PCA. |

| Error code: | 53.10.0X |

| Display: | 53.10.0X Unsupported DIMM |

| Description: | An unsupported DIMM is installed. |

| Remedy: | Turn the product off, and then replace the DIMM that caused the error. |

| Error code: | 54.01 |

| Display: | 54.<XX> Error |

| Description: | A sensor error has occurred. Temperature |

| Remedy: | Turn the MFP off, and then turn the MFP on. If the error reappears, record the message and contact support. |

| Error code: | 55.00.YY |

| Display: | 55.00.YY DC controller error To continue turn off then on |

| Description: | DC controller PCA error - 55.00.01 (event code) DC controller memory error - 55.00.03 (event code DC controller no engine response - 55.00.04 (event code DC controller communications timeout |

| Remedy: | Turn the product off, and then on. If the error persists, replace the DC controller PCA. |

| Error code: | 55.01.YY |

| Display: | 55.XX.YY DC CONTROLLER ERROR - To Continue Turn Off Then On |

| Description: | The print engine is not communicating with the formatter. Incoming parity error |

| Remedy: | Turn the MFP off, and then turn the MFP on. |

| Error code: | 55.02.YY |

| Display: | 55.XX.YY DC CONTROLLER ERROR - To Continue Turn Off Then On |

| Description: | The print engine is not communicating with the formatter. Outgoing parity error |

| Remedy: | Turn the MFP off, and then turn the MFP on. |

| Error code: | 55.03.YY |

| Display: | 55.03.YY No Engine Responsesupply unit. |

| Description: | DC controller no response error. |

| Remedy: | 1. Turn the product off and then on. 2. Perform an engine test. 3. Verify the connectors on the DC controller. 4. Replace the DC controller. |

| Error code: | 55.04.YY |

| Display: | 55.XX.YY DC CONTROLLER ERROR - To Continue Turn Off Then On |

| Description: | The print engine is not communicating with the formatter. Communications timeout |

| Remedy: | Turn the MFP off, and then turn the MFP on. |

| Error code: | 55.05 |

| Display: | 55.05 Engine Firmware RFU Error To continue turn off then on |

| Description: | An issue caused the firmware upgrade to fail. |

| Remedy: | - Turn the product off, and then on. - Restart the firmware upgrade. - If the problem continues, try a different firmware file. |

| Error code: | 56.01 |

| Display: | 56.XX ERROR To continue turn off then on |

| Description: | A temporary printing error has occurred. unknown input device, selected media input unavailable |

| Remedy: | 1. Turn the device off, and then turn the device on. 2. For 56.01 errors, check the connections to the input device (optional 1 x 500- or 3 x 500-sheet feeder.) For 56.02 errors, check the connections to the optional stapler stacker. 3. Remove all non-HP paper-handling devices. 4. Perform a RFU. |

| Error code: | 56.02 |

| Display: | 56.XX ERROR To continue turn off then on |

| Description: | A temporary printing error has occurred. unknown output device, selected media output bin unavailable |

| Remedy: | 1. Turn the device off, and then turn the device on. 2. For 56.01 errors, check the connections to the input device (optional 1 x 500- or 3 x 500-sheet feeder.) For 56.02 errors, check the connections to the optional stapler stacker. 3. Remove all non-HP paper-handling devices. 4. Perform a RFU. |

| Error code: | 57.03 |

| Display: | 57.03 ERROR |

| Description: | Fan FN102 has experienced an error. |

| Remedy: | 1. Inspect fan FN102 to determine if its rotational movement is being obstructed. 2. Verify that the fan connection at connector J75 on the DC controller PCA is securely seated. 3. If the error persists, replace the fan. |

| Error code: | 57.04 |

| Display: | 57.04 ERROR |

| Description: | Fan FN101 has experienced an error. |

| Remedy: | 1. Inspect fan FN101 to determine if its rotational movement is being obstructed. 2. Verify that the fan connection at connector J64 on the power supply PCA is securely seated. 3. If the error persists, replace the fan. |

| Error code: | 57.07 |

| Display: | 57.07 ERROR |

| Description: | Fan FN301 has experienced an error. |

| Remedy: | 1. Inspect fan FN301 to determine if its rotational movement is being obstructed. 2. Verify that the fan connection at connector J65 on the power supply PCA is securely seated. 3. If the error persists, replace the fan. |

| Error code: | 59.30 |

| Display: | 59.<XY> Printer Error To continue turn off then on |

| Description: | A product error occurred. fuser motor startup error. |

| Causes: | Fuser motor startup error |

| Remedy: | - Turn the product off, and then on. - Check connections from the specified motor to the DC controller. - Reseat or reconnect the specified motor. - Replace the print cartridge if the problem is with its motors. - Run a service test. - Replace the specified motor. - Replace the fuser. - Replace the DC controller |

| Error code: | 59.40 |

| Display: | 59.<XY> Printer Error To continue turn off then on |

| Description: | A product error occurred. fuser motor rotation error. |

| Causes: | Fuser motor rotation error |

| Remedy: | - Turn the product off, and then on. - Check connections from the specified motor to the DC controller. - Reseat or reconnect the specified motor. - Replace the print cartridge if the problem is with its motors. - Run a service test. - Replace the specified motor. - Replace the fuser. - Replace the DC controller |

| Error code: | 59.5Y |

| Display: | 59.5Y ERROR |

| Description: | A drum motor has experienced a startup error. • Y=0: Black (drum motor 3) (M5) (J121) • Y=1: Cyan (drum motor 2) (M4) (J120) • Y=2: Magenta (drum motor 1) (M3) (M4) (J120) • Y=3: Yellow (drum motor 1) (M3) (J120) |

| Remedy: | 1. Perform the drum-motors component test in the DIAGNOSTICS menu. 2. Reconnect the connectors J120 or J121 on the DC controller PCA. 3. Replace the appropriate drum motor. |

| Error code: | 59.6Y |

| Display: | 59.6Y ERROR |

| Description: | A drum motor has experienced a rotational error. • Y=0: Black (drum motor 3) (M5) (J121) • Y=1: Cyan (drum motor 2) (M4) (J120) • Y=2: Magenta (drum motor 1) (M3) (M4) (J120) • Y=3: Yellow (drum motor 1) (M3) (J120) |

| Remedy: | 1. Perform the drum-motors component test in the DIAGNOSTICS menu. 2. Reconnect the connectors J120 or J121 on the DC controller PCA. 3. Replace the appropriate drum motor. |

| Error code: | 59.B0 |

| Display: | 59.B0 CLEANING MOTOR ERROR |

| Description: | The residual-toner feed motor has failed. |

| Remedy: | 1. Check the toner collection unit. If the unit is full, replace it. NOTE: Toner can clog the feed motor if the toner collection unit is full. 2. Reconnect the residual-toner feed motor connector J63 and connector J155 on the DC controller PCA. 3. Replace the residual-toner feed motor. |

| Error code: | 59.BO |

| Display: | 59.BO CLEANING MOTOR ERROR REPLACE TONER COLLECTION UNIT |

| Description: | This message displays for one of the following reasons: • The cleaning motor is stuck. • The toner-collection unit is full. • The chute at the top of the toner collection unit is clogged. |

| Remedy: | Replace the toner-collection unit |

| Error code: | 59.C0 |

| Display: | 59.C0 Error |

| Description: | Developer motor rotation error. |

| Causes: | Developer motor rotation error |

| Remedy: | 1. Reconnect the connector (J518) on the developing disengagement motor, the connector (J1005) on the driver PCA and the connector (J91) on the DC controller PCA. 2. Run the sensor test in the sensor monitor mode to verify that the developing disengagement sensor is functioning correctly. If it is not, replace the developing disengagement sensor unit. 3. Run the developing unit engagement and disengagement drive test in the actuator drive mode to verify that the disengagement mechanism is functioning correctly. If it is not functioning correctly, replace the developing disengagement motor. |

| Error code: | 59.F0 |

| Display: | 59.F0 Error |

| Description: | Transfer alienation failure. |

| Causes: | Transfer alienation failure |

| Remedy: | 1. Check if the ITB unit is installed. 2. Reconnect the connector (J181) on the DC controller PCA. 3. Run the switch test in the sensor monitor mode to verify that the primary transfer roller disengagement switch is functioning correctly. If it is not functioning correctly, replace the primary transfer roller disengagement switch unit. 4. Run the primary transfer roller engagement and disengagement drive test in the actuator drive mode to verify that the primary transfer roller disengagement mechanism is functioning correctly. If it is not functioning correctly, replace the fuser drive unit |

| Error code: | 59.XY |

| Display: | 59.XY ERROR |

| Description: | A temporary printing error occurred. |

| Remedy: | 1. Inspect the DC controller PCA and verify that the following connectors are firmly seated: • Drum motor (M102) to connector J87 • Feed motor (M101) to connector J91 • Fusing motor (M299) to connector J89 NOTE: There is a cable between the drum motor and the DC controller. Both ends of the cable need to be firmly seated. 2. If the error persists, from the DIAGNOSTICS menu, run the component tests for each motor to verify that they are operating. If any of the motors is not operating, replace the motor. |

| Error code: | 60.02 |

| Display: | 60.02 ERROR |

| Description: | Tray 2 is not lifting correctly. |

| Remedy: | 1. Reconnect connector J115 on the DC controller PCA and the intermediate connector J58. 2. Run the sensor test in sensor monitor mode to verify that the cassette media stack surface sensor is functioning properly. If it is not, replace the pickup assembly. 3. Reconnect connector J56 of the lifter motor. Also check J107 on the DC controller PCA. 4. If the message persists, replace the lifter drive assembly. |

| Error code: | 60.03 |

| Display: | 60.03 ERROR |

| Description: | Tray 3 is not lifting correctly. |

| Remedy: | 1. Reconnect connector J408 on the paper deck controller PCA and the intermediate connector J11. 2. Run the sensor test in sensor monitor mode to verify that the cassette media stack surface sensor is functioning properly. If it is not, replace the pickup assembly. 3. Reconnect connector J15 of the lifter motor. Also check J407 on the paper deck controller PCA. 4. If the message persists, replace the lifter drive assembly. |

| Error code: | 68.X |

| Display: | 68.X STORAGE ERROR SETTINGS CHANGED |

| Description: | An error occurred in the product permanent storage and one or more product settings has been reset to its factory default. |

| Remedy: | Press OK to resume printing. Print a configuration page and check the product settings to determine which values have changed. If the error does not clear, turn the product off and then on. If the message persists, contact an HP-authorized service or support provider. |

| Error code: | 69.X |

| Display: | 69.X ERROR |

| Description: | A printing error occurred. |

| Remedy: | • Turn the product off and then on. • If the message persists, contact an HPauthorized service or support provider. |

| Error code: | 79.XXXX |

| Display: | 79.XXXX ERROR |

| Description: | The product detected a critical hardware error. |

| Remedy: | • Press the stop button to clear the print job from the product memory. Turn the product off and then on. • Try printing a job from a different program. If the job prints, go back to the first program and try printing a different file. If the message appears only with a certain program or print job, contact the software vendor for assistance. If the message persists with different programs and print jobs, try these steps. • Turn the product off. • Disconnect all cables to the product that connect it to the network or computer. • Remove all the memory DIMMs or thirdparty DIMMs from the product. Then reinstall the memory DIMM. • Remove the EIO device from the product. • Turn the product on. If the error no longer exists, follow these steps. • Install the DIMM and EIO device one at a time, making sure to turn the product off and then on as you install each device. • Replace the DIMM or EIO device if you determine that it causes the error. • Reconnect all cables that connect the product to the network or computer. |

| Error code: | 8X.YYYY |

| Display: | 8X.YYYY EMBEDDED JETDIRECT ERROR |

| Description: | The embedded HP Jetdirect print server has encountered a critical error. |

| Remedy: | • Turn the product off and then on. • If the message persists, contact an HPauthorized service or support provider. |

Название

HP 504A Тонер-картридж черный (5000 стр.)

HP 504X Тонер-картридж черный (10500 стр.)

Двойная упаковка черных картриджей HP-504X

HP 504A Тонер-картридж голубой

HP 504A Тонер-картридж желтый

HP 504A Тонер-картридж пурпурный

HP Емкость отработанного тонера

HP Печь в сборе 220V

HP Комплект картриджей со скрепками